Basement to Billions

Basements are places of possibility, where innovators work on ideas, startups play out their potential, and entrepreneurs grow their inventory. While garages may get more media attention as famous startup locations, many famous companies began in basements, including Amazon, Virgin Group, Qualtrics and Under Armour. Micron, one of the world’s largest producers of computer memory and computer data storage, also enjoys its own basement startup story. Micron grew from a basement business idea to a $30 billion global company and is now one of the largest semiconductor companies in the world. Micron celebrates 45 years in the semiconductor business on October 5, 2023.

Micron was founded in 1978 as a small, four-person technology consulting firm in the basement of a dental office on Cole Road in Boise, Idaho. The company was founded by Dennis Wilson, Doug Pitman, and brothers Joe and Ward Parkinson. The spark that ignited Micron's move into chip development in 1981 was a blend of audacity and necessity.

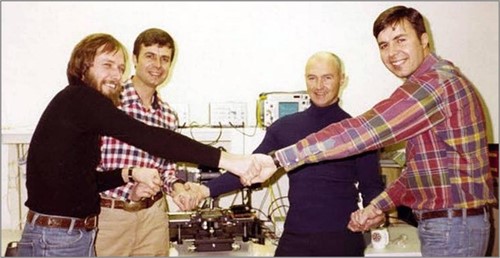

Early members of Micron’s team in 1978 included, from left, cofounder Dennis Wilson, cofounder Joe Parkinson, employee Bob Pratt and cofounder Ward Parkinson. Provided by Micron Technology Inc.

"We had not planned to go into computer chip manufacturing, and our venture into it was totally fortuitous," says founder and former Micron CEO, Ward Parkinson. "The shift to memory manufacturing began after we lost our consulting contract. From there we just rocked and rolled." This group of visionaries, now scrambling to revise their initial vision, embarked on a journey that would reshape the technology landscape forever.

Cost-effective Innovation Fuels Micron’s Growth

Semiconductors are the computational backbone of data storage and many devices we rely on, such as laptop computers, USB drives, smartphones, solid-state drives, smart cars, and much more.

Micron began its technological evolution by manufacturing 64K DRAM chips after the completion of its first wafer fabrication unit in 1981. Three local men put up the initial money for product development and Micron secured the backing of major Boise investors, including billionaire potato farmer J.R. Simplot. Simplot's big investment attracted the attention of its customer McDonald's, which also invested tens of millions of dollars in the new semiconductor start-up.

J.R. Simplot at 1980 groundbreaking of Micron's first semiconductor manufacturing plant in Boise. Provided by Micron Technology Inc.

Fueled by a burgeoning demand for semiconductor memory chips, the founders believed that they could bridge the gap between the rapid advancement of computing systems and the limitations of existing memory technology. Amidst a climate of skepticism and competition, the founders pressed forward, becoming increasingly steadfast in their goal to revolutionize the semiconductor industry by producing high-quality memory chips at a low cost that would empower the emerging digital era.

Micron’s pioneering spirit led to the introduction of groundbreaking products, including the world's smallest 256K DRAM memory chip in 1984. That same year, Micron became a publicly traded company on NASDAQ. That milestone was followed by the impressive 1-megabit DRAM in 1987. These advancements in miniaturization and technology achievements showcased Micron's innovation and laid the foundation for its ascent as a memory giant.

An Opportunistic Design and Manufacturing Ecosystem

Micron's journey was far from smooth sailing. By the early 1990s, the company had already been through thrilling highs and difficult lows. Those initial years were fraught with challenges – financial hurdles, technical setbacks, and market fluctuations in the chip industry. However, the team's resilience, combined with the consistent capability over the years to deliver industry leading innovations, propelled them forward. As the company evolved, it diversified its portfolio, expanding into different memory technologies and product lines.

With the introduction of Microsoft’s Windows 95 operating system, which required a massive amount of memory, Micron was flourishing and flush with cash. This strong cash-flow position was possible because of smart designs from a world-class R&D center collaborating closely with a highly efficient memory fab operation on the same campus. That design and manufacturing ecosystem saw innovation after innovation while at the same time earning Micron its rating as the most efficient, lowest-cost producer of memory chips. Cash was needed to grow and survive the roller-coaster realities of the fluctuating chip market. That penny pinching philosophy would pay off during the economic downturn of the late 90s.

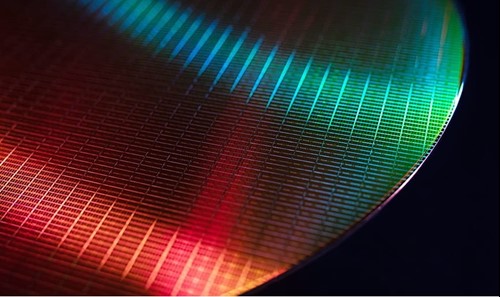

Micron Manufacturing. Provided by Micron Technology Inc.

“1997 was particularly brutal for the whole industry, and Micron was in tough shape,” said Brian Shirley, a former Micron Senior Vice President and a senior advisor in the semiconductor industry. “Most of our cash was invested in a new fab in Utah that we were unable to ramp due to plummeting memory prices. Luckily however, Texas Instruments (TI) memory division was in tougher shape. TI was fed up with the memory industry and sold Micron their manufacturing facilities plus enough cash to ramp them up with our product in exchange for Micron stock. Micron tripled its size overnight. It was a mountain of work, however, because Micron was used to having everything in Boise where we could do things tightly, crisply and quickly. Now, Micron was an international company and had to rethink how to things done efficiently.”

Micron also saw an opportunistic model it could use for ongoing growth and expansion. Keep the debt low, pile up cash for the next silicon slump, maintain a relentless focus on cost-effective R&D and manufacturing, and wait for the next frustrated memory manufacturer who wants to sell as the market bottoms out. They followed this pattern many times over subsequent years.

The dot-com tech crash in the early 2000s proved to be the next difficult downturn where this pattern played out. Micron acquired Toshiba’s DRAM facility in Virginia in 2003. Economic activity again dropped dramatically in the fall of 2008 as stresses in financial markets reached their climax. Micron concluded that to stay competitive, it was time to bid farewell to Boise manufacturing.

“Once Micron switched to 300mm wafers, Boise’s 200mm wafer fabs were too expensive to convert to 300mm production,” said Scott DeBoer, Micron Executive Vice President, Technology and Products. “At that same time, we converted our Singapore and Virginia fabs to 300mm manufacturing and Boise stayed focused on R&D.

Micron Wafer. Provided by Micron Technology Inc.

“The emotional impact of halting Boise manufacturing was profound,” said DeBoer. “Everyone was deeply disappointed, including all who left and all who stayed. The synergy of having R&D and manufacturing co-located had proven invaluable to our success and it was hard to let it go.”

Micron's world-class R&D center in Boise continued as the incubator of ideas that would shape the semiconductor landscape for years to come. The center converted to a 300mm operation starting in 2005 and expanded many times over the next two decades. As memory fabs were closed or consolidated around the U.S. and the world, Boise became the hub where talented engineers and scientists with memory experience came to work and innovate. The result has been a truly remarkable world leading team in Boise.

Semiconductors Become a Flashpoint, Paving the Way for Manufacturing to Return to Boise

2022 marked a pivotal moment in the ever-evolving semiconductor landscape with the signing of the CHIPS and Science Act by President Biden. This bipartisan legislation held the promise of propelling U.S. technological leadership and a declaration of intent to strengthen American manufacturing, secure supply chains, and bolster national security.

“The CHIPS Act is a good start, and was necessary to be globally competitive, but more is required,” said Shirley. “Semiconductor manufacturing has moved offshore in large part due to government subsidies and pro-business policies. Now the U.S. is catching up.”

With the CHIPS and Science Act, along with the anticipation of federal grants and tax credits made available through the legislation, Micron embarked on an ambitious and unprecedented investment to bring cutting-edge memory manufacturing back to American soil and ultimately back to Boise. Micron’s $15 billion manufacturing facility in Boise will be the first new memory fabrication plant built in the U.S. in 20 years.

Micron EVP Scott DeBoer at 2022 groundbreaking of Micron's new $15B semiconductor plant in Boise. Provided by Micron Technology Inc.

This return of memory manufacturing to Boise was not just about erecting factories and bringing people back to the high-tech assembly lines. It was about renewing the synergy between innovation and production. This co-location strategy was about once again fostering a seamless collaboration between the brilliant minds at Micron's research center and the skilled technicians on the fab factory floor.

“It is phenomenal for Micron and the U.S. to bring manufacturing back to Boise,” said Shirley. “We always wanted manufacturing back in Boise, close to R&D. Micron is running one of the best and most advanced semiconductor R&D operations in the world. I’m not sure the larger Boise population understands the value and importance of the work the Micron R&D team is doing, nor how rare those operations are. And now that work will be enhanced by once again having R&D next to world-class manufacturing, it gives Micron the best chance to continue to launch next-generation technologies and stay globally competitive.”

“Having manufacturing back in Boise is a day most employees didn’t think they would ever see again,” said DeBoer. “It’s emotional to consider, especially for those like me who were there when it left. Micron will now be able to do things more quickly, share resources more efficiently, and move things without delay. It’s also a big deal for Boise. It will bring tens of thousands well-paying jobs to Micron and the companies who support them. Memory manufacturing coming back to Boise will generate an unprecedented ecosystem of economic activity.”

A Legacy of Efficiency and Advancement

“One thing I’ve tried to pass on to our country’s leaders is how lucky we are as a country that Micron exists and is thriving. It is a very rare exception,” said Shirley. “Most U.S. semiconductor companies from the last 40 years are either long since bankrupt, have been acquired, or revised their business plans to steer clear from advanced R&D and manufacturing. Intel and Micron are the last two standing in the U.S. with leading-edge capabilities, and most will agree the memory segment in which Micron participates is by far the most competitive.”

Micron Manufacturing. Provided by Micron Technology Inc.

The legacy of Micron is a testament to the power of innovation and determination that can sprout from the most unexpected places. What started as a humble endeavor in Boise became a global technology leader with a staggering 50,000 patents. World-class innovation and cost-effective manufacturing will now be side by side in Boise, ready to shape the digital landscape of tomorrow.

“Micron truly is a national treasure and the global leadership position it holds today is a source of tremendous pride for the thousands of employees who have been part of Micron’s amazing history” concluded DeBoer.